Call Us:080-2338 9400

Call Us:080-2338 9400

GK-1 "GANGA" Direct-On-Line & Star-Delta Motor Starters have robust construction & offers smooth and reliable performance. They are designed to meet the most stringent needs in both agricultural & industrial fields.

Direct-On-Line starters consists of one GK-1 Relay & GK-1 Contractor. Contactor protects the motor against under voltage where as the relay protects the same against overloads.

These starters are provided with a star contactor, delta contactor & line contactor with overload relay. In these starters the motor draws 1/3rd of the normal starting current and hence other loads connected to the same line are unaffected. They are of 2 types.

In this type of motor starter the 'START" button is pressed till the motor picks up to 80-85% speed in Star connection & by releasing the 'START' button the switching from Star to Delta takes place.

TYPE: GF-1

RANGE: 0.5 TO 7.5 HP

GHT'S GF-1 manually operated motor starter is suitable for single-phase motors upto 2hp and three phase motors upto 7.5hp. The starter operates on quick break & trip free mechanism & is designed for smooth & reliable performance.

Wide range of relays is available depending on various AC loads. For actual range see Relay section table.

Once the relay has tripped due to overload the starter cannot be reset until the bimetal elements have cooled down sufficiently.

The silver alloy tipped contacts ensure long electrical life & can be easily accessed for inspection or replacement.

GF-1 Starters are most economical & have wide applications. They are perfectly suited for motor installations where no-volt coil or remote ON/OFF is unnecessary or undesirable. Some applications include switching & overload protection of Air Compressors, exhaust fans, unattended pumps, etc.

Type: GL - 2 / GL - 3

Range: 10 to 30 Hp

GL - 2 type " GANGA" D.O.L Motor Starters have robust construction and offers smooth and reliable performance. They are designed to meet the most stringent requirements of both industrial and agricultural fields. These Motor Starters comply with requirements of IS Standards.

The GL - 2 Relay consists of bimetallic elements, which are individually calibrated & tested for precise operation. An extra 'NO' contact is provided to give clear warning when overloading of motor occurs. Once they relay has tripped due to overload the starter cannot be reset until the bimetal elements have cooled down sufficiently.

The silver alloy tipped contacts ensure long electrical life & are bounce free when closed. They can be easily accessed for inspection or replacement.

Laminated 'E' stampings are used for construction and are designed for low loss.

Shading rings are provided to reduce hum & chatter.

Coils are layer wound and

are designed for long life. They consume less power & can withstand wide voltage

fluctuations particularly in rural areas.

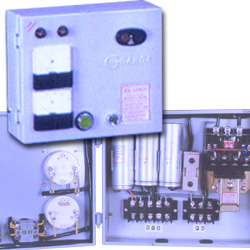

Protection of valuable motors cannot be achieved by mere switching 'ON' & 'OFF' devices. Where as GK-1 type control panels are designed for absolute protection of motors against single phasing, under voltage, overload & dry running.

1PH Control Panel : Range 1/1.5/2 Hp

D.O.L Control Panel : Range 3-8 Hp

Star-Delta Control Panel : Range 7.5-15 Hp

Control Panels mainly consists of GK-1 range of Overload Relays, Contactors along with Single Phase Preventers; Back up Fuses, Ammeter, Voltmeter, Pilot lamps & other panel accessories.

Consists of bimetallic elements tested & calibrated to protect the motor against overloads.

Connects the motor to the main supply when activated by the "START" button. They protect the motor against under voltage. Weld resistant contacts having tested for millions of operation has been used for the construction of contactors.

It mainly protects the motor against single phasing in the mains. Also protects the motor against dry run by tripping at the instant the water level decreases from the desired level.

3 nos. of rewireable fuse units are mounted in the panel and are connected in series with each phase. They are used to protect the motors against short circuit.

The enclosure is fabricated using thick steel sheets and later powder coated to a glossy finish. Three pilot lamps are mounted at the top for phase indication. The Ammeter and Voltmeter used has 1% error & is of class 1 accuracy. The Ammeter reads the exact current drawn by the motor and the Voltmeter indicates the phase voltage as selected by the phase selector switch when the voltmeter button is pressed.

Consists of Starting & Running Capacitors along with overload relay, contactors & other panel accessories.

precise Auxiliary contact blocks are used along with relays and contactors for the necessary switching of motors from Star to Delta connection.

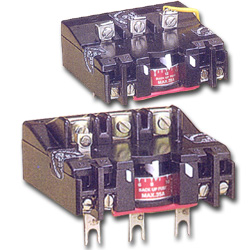

These types of relays consist of bimetallic elements, which are individually calibrated and tested for optimum protection of motors against overloads.

The tripping curve shows the inverse time characteristic of all bimetallic relays starting from cold condition.

Once the realy is tripped due to overload it cannot be reset immediately as the relay has a specific reset time. Resetting is done maually. Wide range of relays are available depending on various AC loads. For actual range see RELAY SELECTION TABLE.

Depending on their specifications and ratings relays are classified in the following

types:

Type GK-1 Relay; Range: (0.6-1A) to (13-21A)

Type GL 0/GL1/GL1.5 Relay; Range: (0.6-1A) to (20-32A)

Type GL2/GL3 Relay; Range: (9-14A) to (28-42A)

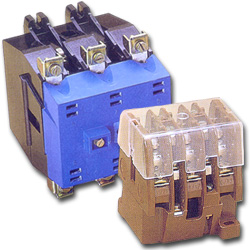

GL0/GL1/GL1.5/GL2/GL3 contactors are rugged & designed for trouble

free switching of AC motors and other AC loads. They can withstand high ambient,

humidity, under voltage conditions and frequent starts. Depending on their current

ratings & specifications they are classified as fallows,

Type : GL0/GL1/GL1.5 Range : 12A/16A/25A.

Type : GL2/GL3 Range: 32A/40A

The Bakelite housing of the contactor has a very high degree of insulation. Current carrying contacts are of silver alloy and hence have a long electrical life. Auxiliary contacts are provided for control and interlocking purposes. Laminated 'E' stampings are used for the magnet construction and the coils are designed for long life and can withstand wide voltage variations.

For further details refer TECHNICAL DATA

GHD Type Overload Relays are compact in design.

They also have bimetallic elements, which are calibrated and tested for precise

operation. Their tripping curve is similar to GK-1 type of relays except that they

operate on differential mechanism technique. Resetting of GHD Relay can be done

both manually or automatically.

Range (0.3 - 0.48A) to (22 - 30A)

These heavy-duty contactors have a robust construction and are designed for trouble free and long operation life. They can withstand high ambient, humidity, under voltage conditions and frequent starts.

The silver alloy contacts provide good weld resistant characteristics and have a long electrical life. They are bounce free when closed and have been tested for millions of operations. Precisely tested Auxiliary Contact block operating 'BREAK BEFORE MAKE' principle can be provided for control and interlocking purposes.

Coils are designed to withstand wide voltage variations and consume less power. They are moulded by DMC material thus resisting moisture and physical damage. Laminated 'E' & 'I' stampings are used for construction of magnet. Shading rings are provided for quiet operations.

The main contacts can be easily accessed ands inspected by removing the screws of

the arc chamber without disturbing the electrical wiring or altering the contactor

mounting position. The unique feature of these type of contactors is that they have

common physical mounting dimensions & are flexible, in the sense that they can be

electrically upgraded from 16A to 25 A or 40A & vice-versa just by changing the contact

system.

For further details refer TECHNICAL DATA

Protection of valuable motors cannot be achieved by mere switching ON and OFF devices. Where as GHD type control panels are designed for absolute protection of motors against single phasing, under voltage, overload & dry running.

1PH Control Panel : Range 1/1.5/2 Hp

D.O.L Control Panel : Range 3-8Hp

Star-Delta Control Panel : Range 7.5-15Hp

These heavy-duty contactors have a robust construction and are designed for trouble free and long operation life. They can withstand high ambient, humidity, under voltage conditions and frequent starts.

The Construction is similar to that of GK-1 Control Panels except that GHD type overload relays & Contactors are used. These control panels can be designed to operate on low voltages as the moulded coil of Contactors are designed for low pick-up & drop down voltage. They are specially designed to meet the most stringent needs in both agricultural & industrial fields.